We will introduce peripheral equipment necessary for handling die holder.

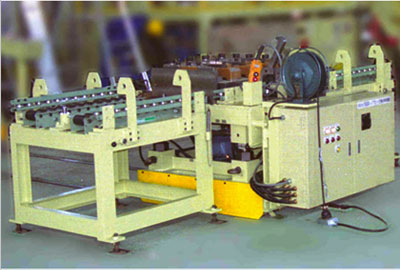

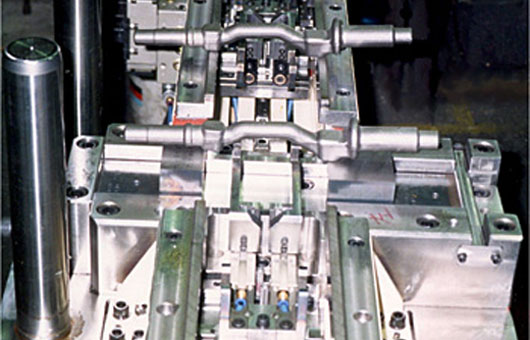

The cassette (sub-holder) must be carried in and out in a short time.

With our bogie, it is possible to exchange die safely and in a short time, and we can accommodate any factory layout.

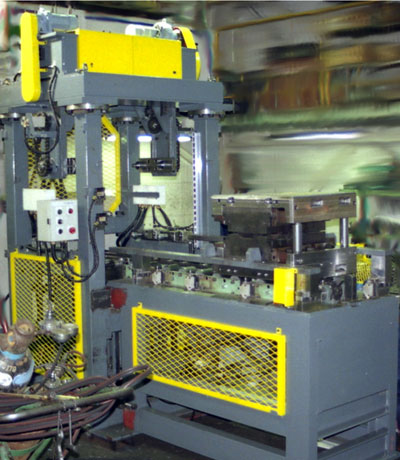

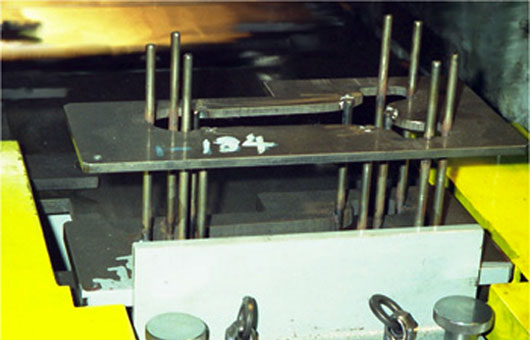

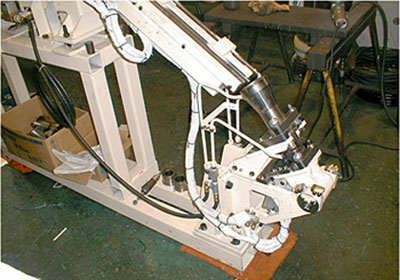

When taking outside steps, reversing the upper die holder realizes safe work of tool change.

We will shorten changing time by cooperation with HPC type die holder.

Reversing heavy objects is a very dangerous task.

Our products contribute to customer safety.

When taking outside steps, reversing the upper die holder realizes safe work of tool change.

Perform the operation of separating and assembling the upper and lower die holders by automatic operation.

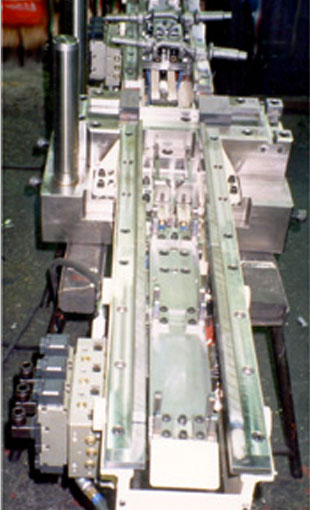

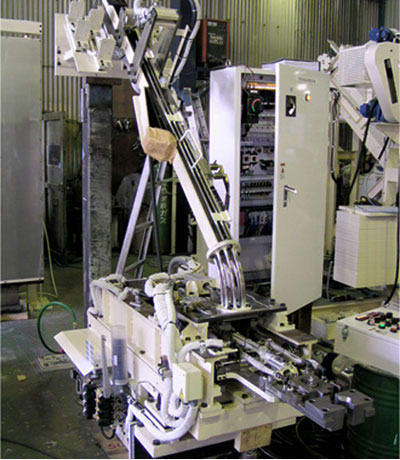

Experience is essential to the production of materials and product transport equipment.

We take advantage of many years of experience, we are helping to labor saving.

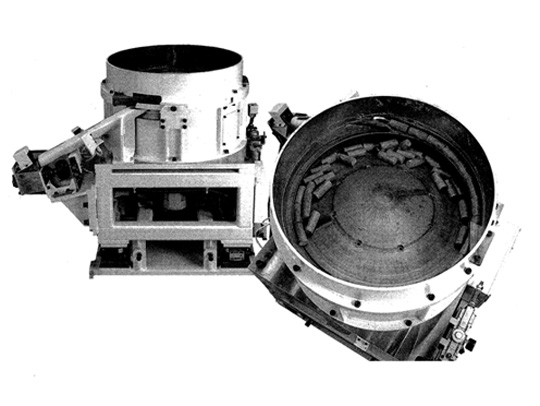

Corresponding to coining safety work by adopting magazine.

It is possible to make LINE consistent with the finish inspection process by controlling the work loading and unloading.

A movable cup is installed at the exit of the chute, and the position where the material is raised becomes the zero station as it is.

A chuck type material supply device is installed at the exit of the chute. With the AC servo, the material conveying distance can be adjusted.

[Characteristic]

-With low noise, no dust scattering, scales etc. attached to the work are collected in one place.

-Because the soundproof box is unnecessary, the alignment supply status of the work can be easily seen.

-Excellent abrasion resistance, no vibration, no breakage, improved capacity utilization rate It is possible to drastically reduce maintenance costs, as well as long life and maintenance free.

We manufacture all kinds of tools related to forging, including ram and saw block of air drop hammer with high quality and short delivery time. Please do not hesitate to contact us.

-Ram

-Saw Block

-Cutting blades and die holder parts

-Cotter

-AMP parts

-Inspection jig

Reusing cutting machine fluid and die releasing agent

No filter, cheaper, effortless filtration equipment

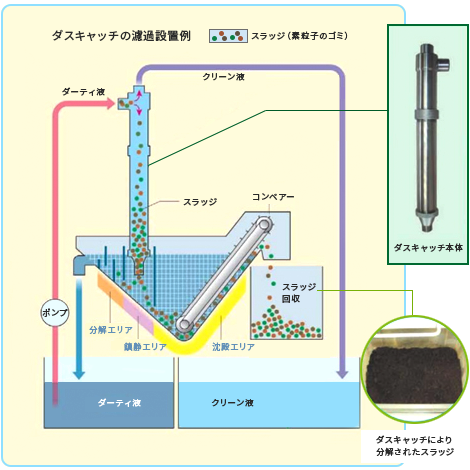

By using the filtering equipment with centrifugal separation (cyclone) for temporary treatment of the dirty liquid, you can separate sludge from clean liquid and collect the sludge efficiently.

For those who are already using the filter already using filter, after using das catch for the primary processing, passing the coolant liquid through the current used filter greatly improves the dirt of the filter, It is also useful for reduction and environmental cleanup.

Did not you spend time and effort on filter replacement work etc in the current machine?

Das catch greatly reduces such costs.

· No filters (paper, cloth, filter etc.) necessary means no filter replacement costs.

· No clogging, no maintenance required.

· Much less cleaning the inside of the coolant tank.

· Sludge discharge can be done by a timed automatic electromagnetic valve.

· As it is manufactured by processing stainless steel, it is resistant to both oil-based and water-based rust.

(However, please understand that the permeation performance will decrease if using high viscosity liquid)

| Model | DSC-40 | DSC-160 |

|---|---|---|

| Total body weight | 3kg | 6kg |

| Total body length | 481mm | 603mm |

| Total body length | φ58 | φ92 |

| Recommended pump | 0.25 kw or more | 1.5 kw or more |

| Processing flow (Drain close) |

40L L / min | 180 L / min (when 2.2 kw pump is used) |

| 135 L / min. (When 1.5 kw pump is used) | ||

| Target coolant liquid | Water soluble | |

| Target sludge | Iron type, aluminum, abrasive waste (Estimated: something that sinks in water, what can be recognized as grain) | |

| Body material | stainless | |