Therefore, we overhauled the structure of the die holder itself based on the hot forging and die technology and skills acquired at Howa Forging Co., Ltd. We were pioneers in using SKT4 for the body itself and supplied to Toyota Motor Corporation. Moreover, we have made improvements to the conventional integrated structure type changing it into a compact building block-type, and we have developed a single step changeover method using a combination of die conveyors.

Naturally, die holders for stamping press have also been evolving with the spread of stamping presses and changing user demand. However, due to intensifying cost reduction competition, the shift from small-lot large-volume to multi-product small-volume production, and the automation of the stamping press, decrease of changeover time to shorten downtime became increasingly important.

Therefore, we overhauled the structure of the die holder itself based on the hot forging and die technology and skills acquired at Howa Forging Co., Ltd. We were pioneers in using SKT4 for the body itself and supplied to Toyota Motor Corporation. Moreover, we have made improvements to the conventional integrated structure type changing it into a compact building block-type, and we have developed a single step changeover method using a combination of die conveyors.

The tree whose name we are using, “Kusunoki (camphor)” is a long-lived, big tree exceeding 30m in height. We hope to grow like the camphor tree, and to this end, we will continue to improve and evolve based on our achievements and customer feedback. Also, as a forging industry “concierge”, we will continue to respond to various demands beyond the die holders field. We will strive to create and provide more excitement, satisfaction, and advantages to our customers.

Kusunoki Dieholder is a gathering of people who love making things to believe that making people happy with themselves by being pleased with our customers by providing excellent labor saving facilities.

Forging is a construction method suitable for mass production of automotive parts which are required for durability.

Kusunoki Dieholder aims to be the best in Japan with the help of making forged companies safely, comfortably, quickly, accurately, centering on the following business items.

Die holder for various forging presses

Development · design · production · remodeling · overhaul, and main crack part welding repair

Forging and repair of hammer parts

Ram · Saw Block, Ram Guide, Intermediate Base, Cotter

Manufacture of aprecita parts

Grip dies, tool holders, etc.

Automation / labor saving device

Material supply device, conveyor, transporting cart, inverting machine, cyclone type filtration device “Das catch”

We would be pleased if you delighted our customers with delivering good products that promised good greetings, good faith hospitality, speedy response, and can only be made with teamwork of all Kusunoki.

| Company name | Kusunoki Dieholder Co., Ltd. |

|---|---|

| CEO | Mitsuhiro Miura |

| Date of establishment | March, 1967 |

| Capital | 60 million yen |

| employee | 40 people |

| location | [Office & Atsuta Plant] 4-13 Sanbancho, Atsuta-ku Nagoya, Aichi Prefecture 456-0056 TEL.+81-52-651-7138 IPTEL.+81-50-3536-1643 FAX.+81-52-653-0020 [Minato Plant] 3-1 Minamijuban-cho, Minato-ku Nagoya, Aichi Prefecture 455-0007 TEL.+81-52-655-6771 FAX.+81-52-652-2516 |

| Business item | Die holder for various forging presses Development · design · production · remodeling · overhaul and main crack part welding repair Hammer parts Ram / saw block (including crack welding repair), ram guide, intermediate table, cotter Apparatus parts Grip dies, tool holders, etc. Automation / labor saving device Material supply device, Die holder and cassette transport cart / Inverter, Conveyor |

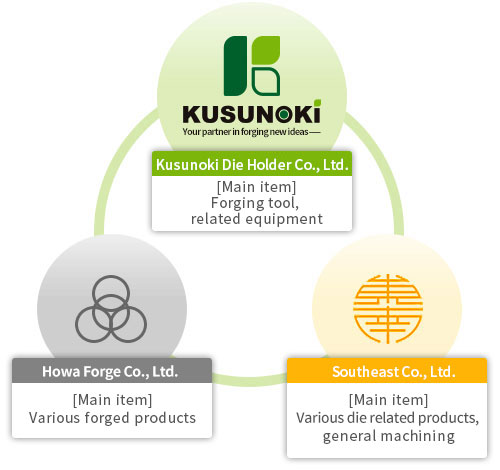

| Affiliate | Howa Forging Co., Ltd. Tohnan Seiki Co., Ltd. |

| Business Partner Bank |

Okazaki Shinkin Bank / Port Branch Bank of Tokyo-Mitsubishi UFJ · Rokkon machi branch |

Our corporate group contributes to society by raising customer satisfaction through offering dies and die parts, forged products and forging equipment parts, tools and labor-saving equipment and more.

Howa Forging, Tonan Seiki and Kusunoki Dieholder each take advantage of their specialty field to help the Group meet customer needs.

| March 1941 | Established a forging company for personal foundation in Sanbancho, Atsuta-ku Nagoya. |

|---|---|

| April 1954 | Becomes a corporation, and becomes Howa Forging Co., Ltd. |

| June 1957 | Constructed a forging factory in Minato-ku, Nagoya City, and started operations as Southeast Forging Co., Ltd. (the predecessor of Southeast Seiki Co., Ltd.) in the same year. |

| August 1961 | Toyoharu Forging Co., Ltd. moved the forging factory to Anji City. The ground remains as a die factory. |

| March, 1967 | As a die manufacturing industry, Kusunoki Dieholder Co., Ltd. was founded in Gotan-cho, Atsuta-ku. |

| 1968 | Kusunoki Dieholder Co., Ltd. merged with Toyawa Forging Co., Ltd. Atsutada Die Factory. |

| 1972 | Southeast Forging Co., Ltd. shifts from forging to machining, and the company name is Tonan Seiki Co., Ltd. |

| April 1992 | In Anjo-shi Nezaki cho, Tohno Seiki Co., Ltd. HTK factory was built by taking the first letters of alphabet of Toyohi Forging Co., Ltd., Southeast Seiki Co., Ltd. and Kusunoki Dieholder Co., Ltd. |

| February 2005 | Head office of Tohnan Seiki Co., Ltd. moved to Anjo city next to HTK factory. The site will be the Kusunoki Dieholder Co., Ltd. Harbor Factory. |