Our main products are die holders for hot forging press.On this page, we explain what a die holder is for all people interested in our company, including those viewing this site, those looking for a job, and the family members of our employees so that everyone can better understand our business.

Before explaining about die holders, first, let us talk about metal processing.

Automobiles are indispensable to life as we know it today.

They are made up of various parts many of which are made of metal.

To manufacture these parts, it is necessary to process metal into the desired shape.

There are three main ways of processing metal as explained below.

There are various methods other than the three mentioned here and each has advantages and disadvantages. The appropriate processing method is selected according to the characteristics of the material, the shape of the part, and the intended use.

More details about the forging method

Forging, like the characters suggest, is a way to “create” through “tempering”. Therefore, it is a method suitable for making parts that need to be durable, such as wheel and engine parts.However, when using the “free forging” method as in forging a sword, it is very hard to obtain the same shape. Therefore, we make what we call a “die” for forging.A die is made of an upper half used to shape the top side of the part (upper die) and a lower half (lower die) for the bottom side. A heated rod-shaped metal material is placed in between and the die is hit with force to shape the rod into the required metal part.However, hitting once is not enough to produce the desired shape, so it will be dieed through stages such as “crushing”, “rough forging”, and “finishing”. This method is called “die forging” and is widely used for making automobile parts.

Japan Forging Association

Die forging metalwork press machines

Machines are necessary because it is impossible to move the die, especially the upper die, up and down by human power only. One such machine is called a press. To complete the three stages of “crushing,” “rough forging,” and “finishing” for example, with top and bottom dies for each process, you need three lower dies and three upper dies.

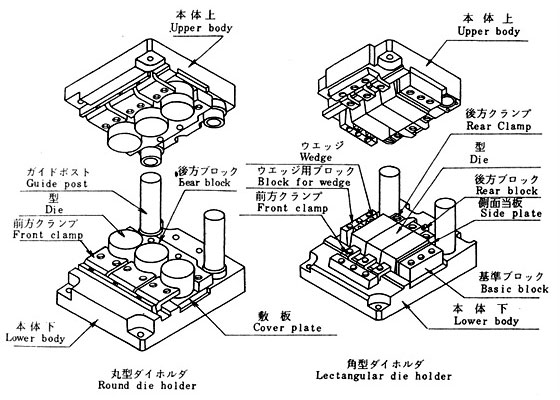

What keeps these dies fixed to the press machine are “die holders.”

Die holders are important not only for fixing the die to the press machine but also as guides that move the die up and down with precision, leading to enhanced product accuracy.

HPC die holders developed for the first time in Japan in 1982 can contribute to shortening the time for die replacement in the forging press, saving power, labor, and space, and dramatic improvement in safety, thus revolutionizing the industry. Our HPC die holders are now installed on over 150 lines in Japan and overseas.

Read more